Integrate world-class FANUC automation solutions with confidence.

Looking to advance your automation strategy? As an Authorized Fanuc System Integrator, we provide a wide range of robot solutions for plastic injection molders, backed by our signature aftermarket service.

Talk with salesWhy choose ARI

At ARI, we are here to help your plastics manufacturing operation get to the next level of automation, for both factory managers and engineers alike.

For Owners & Managers

We provide automation solutions that meet your goals – increasing profits for business growth and sustaining a competitive advantage.

Fast Delivery and Aftermarket Support. We know that uptime is critical to success in molding. This is why we focus on quick delivery and installation, as well as aftermarket support.

Experts in Your Field. As part of The Absolute Group of Companies, ARI brings a team with extensive injection molding expertise for successful injection molding automation projects.

Technical Depth. Our Engineering and Service Teams use state of the art tools, from cloud-based solid models and automation simulations to project tracking systems. We’re all about keeping everyone on the same page to ensure we get it done right, on time, and on budget.

Committed to Your Success. We know what it takes to build great companies – delivering value that keeps customers moving forward. Our high employee retention rate together with our strong commitment to employee training is a powerful combination that works for you on every project.

For Engineers

As the person assigned to implement and maintain automation in your facility, we make sure each step of our process is easy for engineers to review and track.

Project Management. We make it easy for you to track project status, cross all the t’s and dot all the i’s. Our weekly customer meetings and project gantt charts help shine a light on the critical path to make sure we hit target deliveries.

Solid Model Design. There is no better way to review a design than seeing it in 3D. Every project is done using state of the art Solid Modeling software that lets you assess and optimize the design.

Documentation and Training. Project documentation lets your team install, commission, and troubleshoot with ease. We encourage customers to visit our facility during the final stage of production for “Pre-Installation” training, which is then followed up with “Post Commissioning” training.

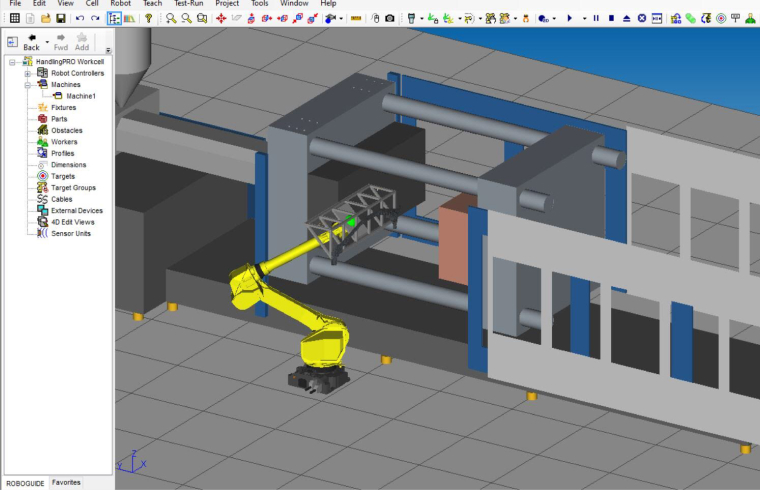

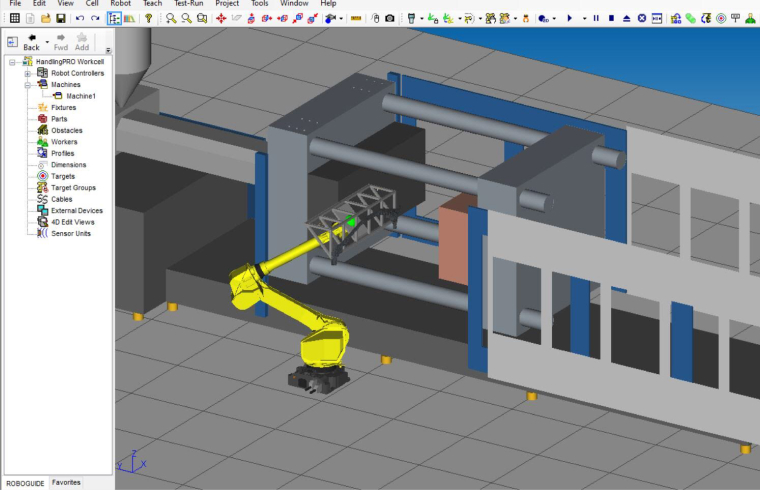

Simulations for High Performance. We build and run accurate simulations for every project using Fanuc’s acclaimed ROBOGUIDE software to ensure performance expectations are met, well in advance of the install.

Ongoing Support. All ARI-Fanuc Automation cells are equipped with Fanuc’s ZDT (Zero Down Time) remote access functionality to ensure that your automation is running well, long after the install.

How we work

With top-of-the-line engineering and commitment to customer service, our process is built to deliver results and maintain robot up-time for our clients.

Streamlined Projects

All of our system integrator projects follow a process that we’ve carefully calibrated over the years. From simulations and 3D modelling, to factory acceptance testing, we ensure you achieve your target results.

Advanced Tools

We use the latest software tools for solid model design, simulation (ROBOGUIDE), and project management to streamline the startup process.

Reliable Customer Support

Robust customer support is the backbone of ARI. Our services include technical service (over the phone, through video conference, or on-site), documentation and training, and aftermarket parts supply.

Servicing North America for 10+ years with 750+ robots installed

As a part of the Absolute Group, ARI shares a service and support team with Absolute Haitain and Absolute Machinery. The combined resources of the company include 3 facilities across New England, the Midwest and South, 25+ service technicians, training classrooms, and thousands of years of collective experience in the organization.

Products you know and trust

We work with FANUC’s 6-axis robots, SCARA robots, and cobots (collaborative robot) for plastics manufacturing. Don’t see a robot below that suits your needs? Get in touch and our experts will help you choose the right automation solution for the job.

M-10iD Series

The fast, compact solution to all your small handling jobs in confined work areas.

M-20iD Series

Slim and strong industrial handling robot for multi-purpose medium payloads.

M-710iC Series

The slim wrist, small footprint robot for medium payloads and a wide range of applications.

SCARA Series

The high-speed, precision solution for applications such as assembly, pick and place, testing/inspection and packaging processes.

CRX Series

The latest collaborative robot designed to make installation and programming your cobots easier than ever before.

Talk with sales

Ready to advance your automation strategy? Send us an email at info@absoluterobot.com or call us at (508) 792-4305 and our sales manager will be in touch as soon as possible!

Send us an email